Have you ever felt vibrations coming while boating that feels like a humming sensation? If so, the cause could be the effects of a serious engine issue or even structural damage to the hull or propulsion system. These vibrations can cause instability and potential long-term damage to the vessel, so it’s important that they are addressed as soon as possible.

Excessive vibration on boats can originate from a variety of sources such as loose steering parts or engine issues — so how do you determine and fix the underlying cause? Triad Diagnostic Solutions is here to help with our complete lineup of Jaltest Marine Kits.

Identifying the Source of Vibration on Your Vessel

Experiencing excessive vibration while exploring the open waters is not only uncomfortable but also a sign of a potential mechanical issue. Identifying the source of these vibrations is crucial to ensure the safety and efficiency of a vessel and its occupants.

The first step is to isolate the location of the vibration, which can be done by observing the frequency and vibration levels. Is the vibration coming from the engine, propeller, or another component? Is it happening at a particular speed or in certain conditions? These are important questions to consider when starting to troubleshoot odd ship vibrations. In some cases, it may be caused by imbalanced propellers, damaged bearings, or worn-out engine mounts.

Keeping a routine maintenance schedule with the help of the Jaltest Marine Diagnostic Kit for Boats and yearly inspections on vessels can help prevent these issues. But if your customers do experience vibrations, it is important to address them promptly to avoid further damage or safety hazards.

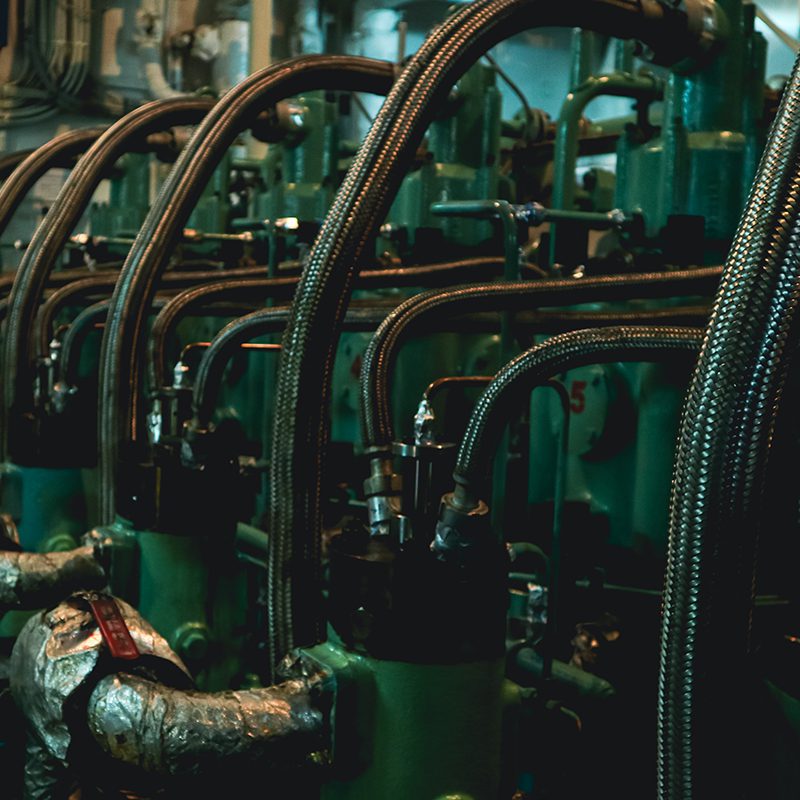

Inspecting the Engine and Propeller for Unusual Wear or Damage

One area to inspect when troubleshooting vibrations is the engine and propeller for any unusual wear or damage. Any damage or wear on these parts can throw off the balance and cause vibrations that can affect the performance and safety of a vessel. Check for bent blades, corrosion, a bent shaft, a fouled propeller, the shaft line, intermediate shaft, thrust bearing, lower unit damage, or any other issues that may be causing the vibrations in the propulsion system. If nothing seems obvious, then it’s time to get down to the diagnostics and troubleshooting things you can’t see.

With the right marine diagnostic tools, engine and propeller issues on outboard motors will be easier to spot and repair. Still, you should plan on doing a thorough check or run full diagnostics to pinpoint the cause of unusual vibrations.

Checking for Loose Mounts, Hoses, and Connections on the Engine

Other possibilities for vibrations on a vessel include loose engine mounts, hoses, and connections on the engine. Make sure to thoroughly inspect all connections and tighten any loose bolts or clamps. It’s also a good idea to visually inspect all hoses for any signs of wear or cracks.

Loose or damaged mounts, hoses, and connections can cause vibrations that can be felt throughout the entire vessel and can also lead to additional mechanical problems. To properly diagnose the issue, it is recommended that you inspect the entire engine and surrounding components like the engine mount thoroughly.

Examining Mechanical Components for Balance Issues or Alignment Issues

When troubleshooting vibration problems on a boat, it’s essential to examine the mechanical components for balance and alignment issues. These can include everything from misaligned props to warped shafts or damaged bearings. These issues could be caused by a variety of factors, such as wear and tear over time or improper installation.

If you notice any misalignment or imbalance within these components, it’s important to address the issue promptly to avoid further damage. By taking a thorough, proactive approach to identifying and addressing these issues, you can help ensure a smooth, safe ride on the water for all passengers.

Evaluating the Hull Structure to Check for Possible Structural Damage

Moving through a vessel and trying to identify unusual vibrations also includes inspecting the hull structure to check for possible structural damage. It’s important to know what factors might be contributing to the hull vibration, such as the vessel’s speed and weight distribution. So, while on dry land, inspecting a vessel’s hull structure involves examining it for cracks, dents, or other signs of damage.

These can negatively impact a vessel’s performance and cause vibrations. Start by examining the keel and its support structures, paying close attention to any signs of cracks or deformation. Check for loose fittings, bolts, and corroded fastenings. Don’t forget to inspect the interior spaces of the vessel as well.

Troubleshooting Common Vibration-Related Problems with the Steering System

Navigating the open sea can be an incredible experience, but it’s important to make sure a vessel’s steering system is in good condition before letting you or your clients set sail. One common issue that can arise is vibration-related problems, which can affect the steering system and potentially compromise the safety of crew and passengers.

Troubleshooting these issues requires a keen eye for detail and a strong understanding of the mechanics at play. From inspecting the steering system’s hardware to checking for misaligned propellers, there are a variety of potential solutions to these common problems.

Keep Your Vessels Operating at Their Best with Triad

Excessive vibration on a boat needs to be taken seriously, as they can be caused by structural damage, or indicate misalignment or loss of power. Taking the time to troubleshoot problems using the Jaltest Marine Diagnostics Kit for Boats can save your marine techs countless hours and frustration.

The best way to keep vessels operating at their best is to stay vigilant and make sure to call on diagnostic services like Triad Diagnostic Solutions when you need help diagnosing a problem. Contact us today!

Photo by Francisco Gomes on Unsplash

Photo by Ibrahim Boran on Unsplash