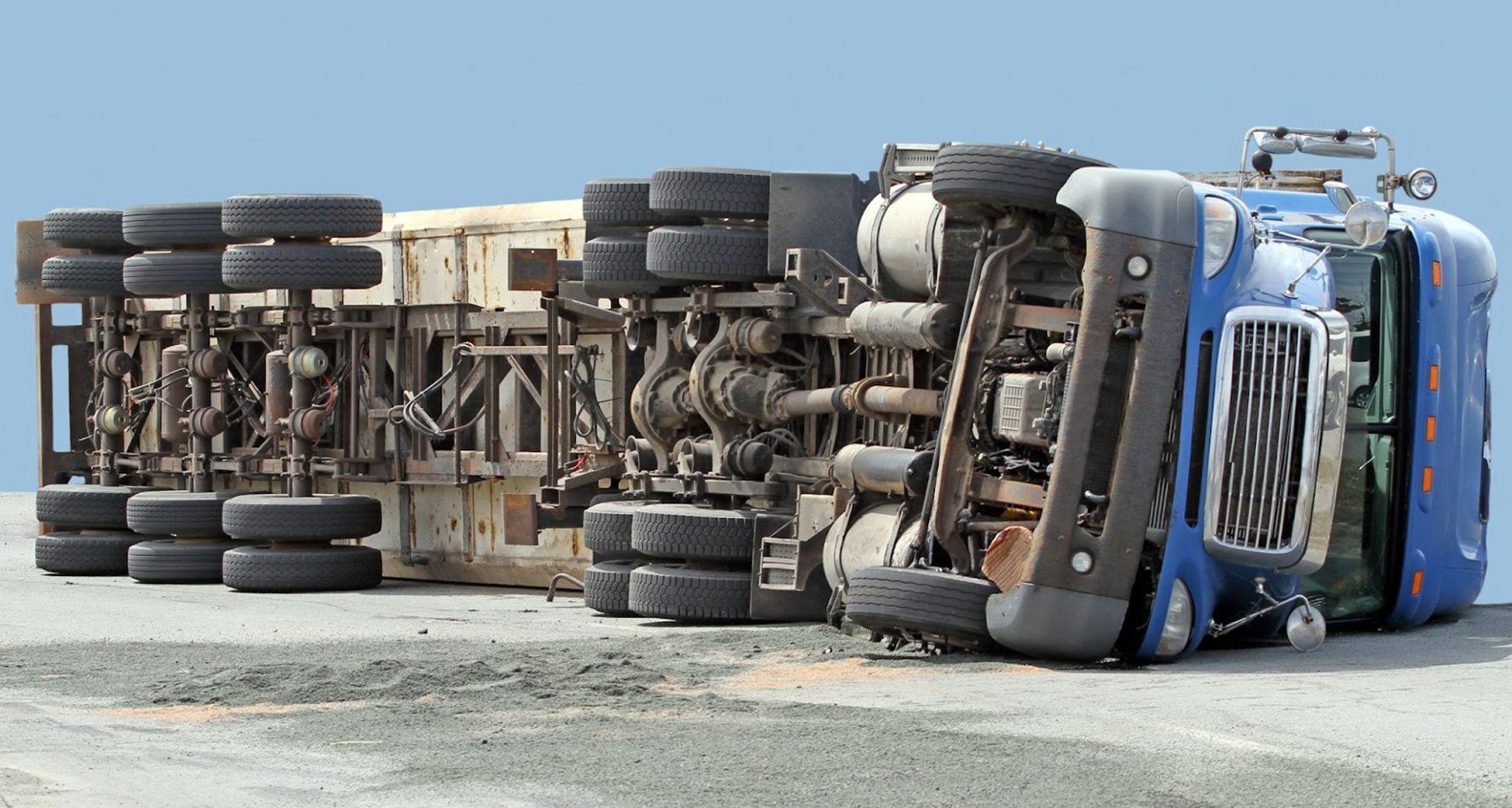

Regardless of the size of your fleet, you want to avoid a rollover at all costs. Not only are rollovers dangerous, but they can also be harmful to your reputation and incredibly expensive. Disaster can strike in an instant, which means stability control sensors are put thru rigorous and continuous work. They constantly send pulses of PSI to the brakes and put the control back in the hands of the driver, avoiding a potentially devastating situation.

Today, Triad Diagnostic Solutions explains the 5 benefits of regular trailer stability maintenance using your Jaltest Commercial Diagnostics Tools. This technology provides additional protection against rollovers and can be especially advantageous in situations where a fleet manager may not know all of the specs of each tractor that hooks up to its trailers.

What is Trailer Stability?

Before we discuss the benefits of trailer stability maintenance, it’s critical that you understand what trailer stability systems do. A trailer roll stability program (TRSP) uses wheel-end controls and sensors to detect conditions that could feasibly result in a rollover. Once these conditions are detected, the system will intervene through brake applications. Typically, this process is enacted before the driver even realizes that something is wrong. There are two types of trailer stability programs: multichannel and single-channel.

Why You Should Properly Maintain Your Trailer Stability Systems

Much like other safety features, your fleet’s trailer stability systems must be properly maintained in order to remain functional and effective. Here are some of the benefits of regular trailer stability maintenance that you should know about.

1. Maximizes Safety

The first and perhaps most prominent benefit of regular trailer stability maintenance involves increased safety measures. Safety features such as trailer stability systems complement safe driving practices. After all, no vehicle safety technology acts as a replacement for an alert and experienced driver using the proper safety techniques. Still, drivers are human, and humans make mistakes.

Trailer stability systems are responsible for kicking in and increasing safety when the right conditions are detected. That being said, these systems cannot and will not function properly without regular maintenance. By maintaining your fleet’s trailer stability systems, you can maximize safety for your drivers.

2. Decreases Downtime

When a rollover occurs, the results can be devastating. What’s worse, according to a study released in 2017, the Federal Motor Carrier Safety Administration (FMCSA) found that there was a 10 percent increase in fatal accidents involving large trucks. Aside from the seriousness of loss of life, these incidents present another problem for fleet managers: downtime and loss of productivity. When a vehicle in your fleet is damaged and effectively put out of service, you’re losing time and money. By properly maintaining your trailer stability systems, you can ensure that they’re always functioning at their best- not only saving lives but eliminating the chances of costly downtime.

3. A Better Understanding of Your Fleet’s Vehicles

When your technicians are tasked with performing regular maintenance on your fleet’s trailer stability systems, they inherently will have a better understanding of how those systems work. The first thing that any driver should know, for example, is the type of stability system installed on the trailer they are pulling.

Knowledge is power when it comes to safety systems such as trailer stability. Technicians can identify the ABS or stability system installed on the trailer by using a diagnostic tool when performing maintenance. Once this is identified, the technician will have a much easier time diagnosing issues and keeping the system running properly.

4. Diagnose Issues with a Trailer Stability System More Quickly

Among all of the causes of faults within a trailer stability system, wiring-related issues are by far the most common. This is because factors like weather and exposure can easily result in wiring issues that can essentially cause the entire system to malfunction. In many cases, the system’s Electronic Control Unit (ECU) isn’t even the primary cause, and this reinforces the importance of your drivers and technicians knowing as much about the installed trailer stability system as possible. This can only be fully attained through regular maintenance and diagnostics with Jaltest tools.

5. Save Money

Finally, when your fleet’s trailer stability systems are properly maintained, you can expect them to function properly at all times. We’ve discussed how this eliminates the chances of fatal accidents, effectively saving lives, but this also saves you money in the long run. A recent article reported that the average cost of a commercial truck accident involving even just one injured person is estimated to be a whopping $148,279. Additionally, this cost rises to roughly $7 million when a fatality is involved.

A loss of revenue is unavoidable when a serious accident occurs involving one of your fleet’s vehicles. In fact, hidden or indirect costs can be four to ten times greater than visible or direct costs. When your company’s profit margins are tight, and competition is great, the ability to be able to control the occurrence of accidents is vital. By performing regular maintenance on your fleet’s trailer stability systems (one of the most important components of safety within your fleet), you can cut down on accidents and save yourself from a devastating financial blow.

Trust Triad Diagnostic Solutions to Help You Keep Your Fleet Running At Its Best!

Now that you understand the importance of properly maintaining your fleet’s trailer stability systems, it’s time to find a commercial vehicle diagnostic solutions provider that you can depend on. Here at Triad Diagnostic Solutions, we have all of the reliable diagnostic tools you need to perform preventative maintenance that makes a real difference.

Among the many popular products we offer, one of the most highly praised is the Jaltest Commercial Vehicle Full Kit that was expertly designed to perform accurate diagnostics in a number of commercial vehicle types. Furthermore, our products come equipped with virtual training sessions to ensure that your technicians can begin using them to their fullest potential more quickly than ever. Feel free to browse our selection of products. Additionally, take a look at our free demo to get a better ideas of how Triad Diagnostic Solutions can help you! Call us today at (317) 939-3690