Emissions system maintenance is one of the most expensive and crucial functions of maintaining today’s diesel engine applications. And whether you own a diesel-powered vehicle or you’re a diesel technician, it’s important to understand diesel particulate filters and how they work.

What Is A Diesel Particulate Filter?

The Diesel Particulate Filter (DPF) is an exhaust after-treatment device that traps particulate matter such as diesel exhaust gases and solid soot particles. It is often the most troublesome of the emission systems and requires regular cleaning by a process called Diesel Particulate Filter Regeneration. The Diesel Particulate Filter Regeneration process burns off diesel soot at high temperatures resulting in ash. After the cleaning, or regenerating, of the Diesel Particulate Filter it can start collecting exhaust gases again.

What Are The Three Types of Diesel Particulate Filter?

The key to maintaining your Diesel Particulate Filter is to ensure it is able to regenerate itself when it fills with diesel exhaust gases or soot. There are 3 different types of Diesel Particulate Filter Regenerations.

Passive Regeneration

Passive Regeneration happens when heat in the engine builds to the point where soot, or carbon, is combined with oxygen to create carbon dioxide. Once the exhaust gases reach higher temperatures the regeneration process will begin automatically taking place as the vehicle is driven normally, such as on prolonged highway drives.

Active Regeneration

Active Regeneration takes place when the engine is not creating the heat it needs. The sensors will read the soot load of the filter to determine when to begin the regeneration. Once initiated, the exhaust temperature increases to burn the soot particles. This process is automatic and can occur at any time the vehicle is moving.

Forced Regeneration

Forced Regeneration happens when Passive Regeneration or Active Regeneration could not occur resulting in soot levels reaching 70% or above. This will result in entering limp mode and will require a diagnostic tool to force the regeneration. This must be done as soon as possible because once the soot level reaches 85%, the Diesel Particulate Filter will need to be removed and cleaned.

This is where Triad and the Jaltest Commercial Vehicle Software Kit can help. The easy-to-use Jaltest application can

-

- Initiate Forced Regenerations

- Run Diesel Particulate Filter Resets

- Run Filter Replacement Resets

- SCR Test and Reset Functions

- And More!

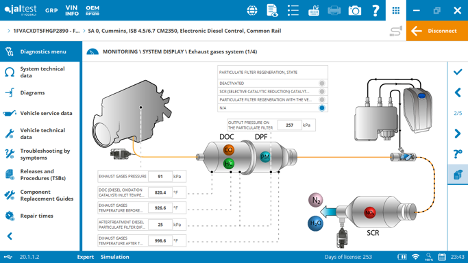

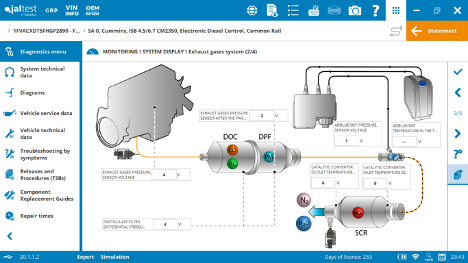

The all-in-one Jaltest application is designed for all makes and models from class 4 to class 8 trucks, to off-highway equipment, and agricultural and farm equipment. In addition, Jaltest also has comprehensive emission system diagrams that allow technicians to monitor temperature, pressure, and electrical system values for data-based diagnostic routines.

Triad’s Single Source Solution featuring Jaltest Software replaces your OEM and aftermarket software with complete coverage, features, functions, and information all in one application. For a webinar demo, contact us here.